TPO Reinforced

TPO waterproof coiled material, namely thermoplastic polyolefin waterproof coiled material, is a thermoplastic polyolefin (TPO) that combines ethylene propylene rubber and polypropylene with advanced polymerization technologyA new type of waterproof coiled material made of synthetic resin as the base material and adding antioxidant, antioxidant and softener can be made into reinforced waterproof coiled material by using polyester fiber mesh cloth as the internal reinforcing material. It belongs to the waterproof product of synthetic polymer waterproof coiled material.

Keyword:

Classification:

Details

Product introduction

TPO waterproof coiled material, namely thermoplastic polyolefin waterproof coiled material, is a thermoplastic polyolefin (TPO) that combines ethylene propylene rubber and polypropylene with advanced polymerization technologyA new type of waterproof coiled material made of synthetic resin as the base material and adding antioxidant, antioxidant and softener can be made into reinforced waterproof coiled material by using polyester fiber mesh cloth as the internal reinforcing material. It belongs to the waterproof product of synthetic polymer waterproof coiled material.

Product specifications

|

project |

describe |

|

packing |

The coiled material is curled into a cylinder and packaged with suitable materials |

|

Product category |

Pmt-3030 reinforced, pmt-3020 backing, pmt-3010 homogeneous |

|

Coil width (m) |

1.0,2.0 |

|

Coil thickness (mm) |

1.2,1.5,2.0 |

|

Coil length (m) |

25 |

|

Area (m2 / roll) |

25,50 |

Note: other specifications can be agreed by the supplier and the buyer

Technical performance index

Use standard GB27789-2011

|

|

project |

H |

index |

P |

|

|

one |

Thickness of resin layer on Intermediate fabric / mm > |

— |

- |

zero point four zero |

|

|

two |

| M—ximum tensile force / N / cm > |

. |

two hundred |

two hundred and fifty |

|

|

stretching] Tensile strength / MPa a |

twelve |

|

|

||

|

strength | Elongation at maximum tension a |

— |

— |

fifteen |

||

|

Elongation at break > |

five hundred |

two hundred and fifty |

. w ‘ |

||

|

throo |

Size change rate of heat treatment% < |

two |

on© |

zoro point five |

|

|

four |

Low temperature bending |

-No crack at 40 P |

|||

|

five |

Impermeability |

0.3MPa, 2h impermeable |

|||

|

six |

Impact resistance |

No water seepage. 0.5km |

|||

|

seven |

Resistance to static load a |

- |

- |

20kg impermeable |

|

|

eight |

Joint peel strength (n / mm) > |

4.0 or coil damage |

|

■ |

|

|

nine |

Right angle tear strength (n / mm) > |

sixty |

- |

four hundred and fifty |

|

|

ten |

Trapezoidal tear strength (n / mm) > |

— |

two hundred and fifty |

|

|

|

eleven |

Water absorption (70 *0. 168h)% < |

four |

|||

|

twelve |

Thermal aging (115,0 |

time |

672h |

||

|

appearance |

No blistering, crack, delamination, bonding and hole |

||||

|

Maximm tensile force retention rate% > |

|

— |

|||

|

Tensile strength retention rate% > |

■ |

|

ninety |

||

|

Bongaticn retention at maxinxm tension% > |

ninety |

|

|

||

|

Eicngaticn at break retention rate% > |

|

ninety |

|

||

|

Lew temperanre bencSng |

ninety -No crack at 40。 |

||||

|

thirteen |

Chemical resistance |

appearance |

No blistering, crack, delamination, bonding and hole |

||

|

Maximni toosite fcxco rGtcntton rat©% A |

|

ninety |

ninety |

||

|

Tensile strength retentkxi rate% > |

— |

■ |

■ |

||

|

Eiccgaticn retention at maxirmm tension% > |

ninety |

- |

ninety |

||

|

Elongation at break retaitfon rato% a |

- |

ninety |

■ |

||

|

Low temperature bending |

ninety -No crack at 40 ,C |

||||

|

fourteet |

Artificial climate accelerated aging |

time |

1500h |

||

|

appearance |

No blistering, crack, dolamination. bonding and holo |

||||

|

Maximum tensile force retention fate% > |

|

ninety |

ninety |

||

|

TensJe strength retenticn rate% > |

|

|

— |

||

|

Elcngation retention at maxinxm tension% > |

ninety |

■ |

ninety |

||

|

Elcngaticn at break retention rate% > |

— |

ninety |

■ |

||

|

Low temperanre be«xJng |

ninety -No crack at 40 P |

||||

A static load resistance is only required for the coiled material used for the pressure paving roof. B the artificial climate accelerated aging time of the products used for the single-layer waterproof coiled material roof is 2500h

Advantages

System advantages

▲ Hot air welding of lap joint: the joint strength exceeds the base metal and the waterproof effect is reliable:

▲ Ultra long service life: the service life of TPO single-layer roof can be proved to be more than 20 years the theoretical service life can reach 50 years;

▲ Green, energy-saving and environment-friendly cold roof: light TPO reflects most of the solar radiation, and the solar reflection index (SRI) is greater than 82. It can be applied to LEED certified construction projects.

Performance advantages

TPO waterproof coiled material combines the performance advantages of EPDM and PVC, and has the weather resistance, low temperature flexibility of the former and the weldability of the latter. This material is different from traditional plasticDifferent materials show high elasticity of rubber at room temperature and can be shaped like plastic at high temperature. Therefore, this material has good processability and mechanical properties, andHigh strength welding performance. The addition of a layer of polyester fiber fabric between the two layers of TPO material can enhance its physical properties, improve its breaking strength, anti fatigue and anti fatiguePuncture ability.

In practical application, the product has the advantages of high aging resistance, high tensile strength, high elongation, wet roof construction, unexposed layer without protection, convenient construction and no pollution.lt is very suitable for the waterproof layer of light energy-saving roof.

Scope of application

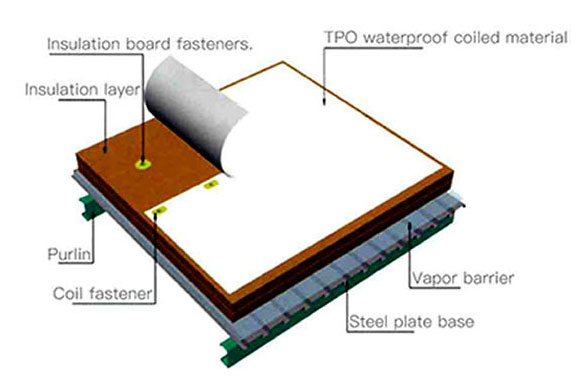

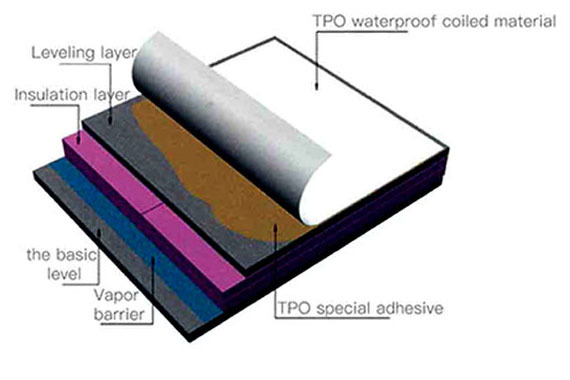

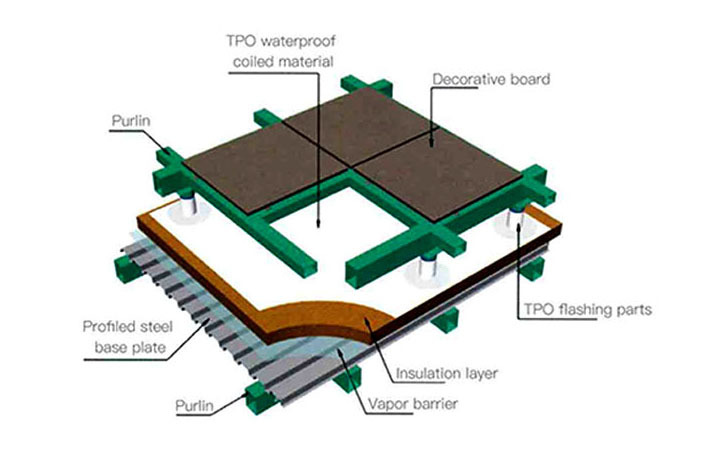

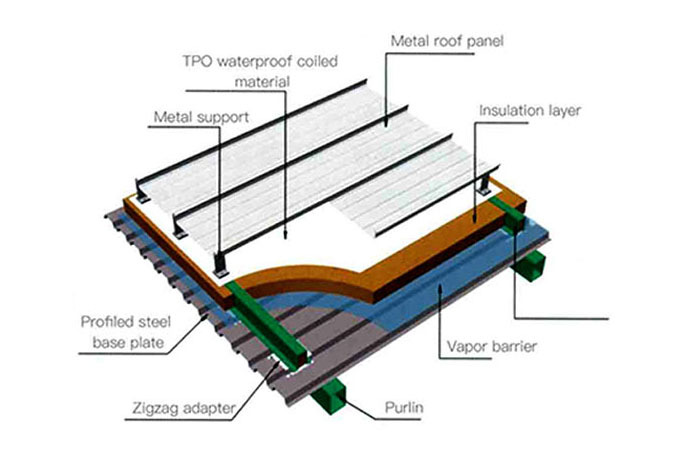

A TPO waterproof layer is compounded in the conventional metal roof system to solve the inherent defects of easy leakage and poor thermal insulation effect of metal roof.

Hollow TPO composite metal roof

waterproof system

Close fitting TPO composite metal roof

waterproof system

Messages