sanded Hdpe pre-applied membrane

Polymer self- adhesive membrane (non asphalt based) waterproof membrane is a waterproof material specially developed for the pre paved part of building waterproof. The membrane is composed of polymer sheet, polymer self- adhesive membrane and anti sticking layer. It is a non asphalt based polymer pre paved waterproof membrane developed to realize the integration with concrete structure. Under pressure, polymer self-adhesive flm and cement slurry without initial setting in concrete penetrate through the anti adhesion layer through creep, forming effective interpenetrating bonding and huge intermolecular force. After the concrete is solidifhed, the gap between the polymer pre paved waterproof membrane and the main body of the structure is permanently sealed to the greatest extent, and the water channeling channel is completely eliminated.

Keyword:

Classification:

Details

Product introduction

The construction and operation of urban subway project cannot be separated from the high-quality guarantee of each subdivisional project. As an important sub project in the underground structure system, the quality and performance of waterproof engineering is directly related to the subway operation safety, later maintenance cost and system structure durability. It is also an important guarantee for urban operation such as traffic conditions and environmental impact along the line.

Technical performance index

|

Proterty |

Value |

Test method | |

|

Thickness/mm |

1.5 | EN 1849-2:2019 | |

| Tensile strength N/50mm | Longitudinal | ≥600 | EN 12311-2:2013 |

| Transversal | ≥600 | ||

| Elongation at rupture(%) | Longitudinal | ≥500 | EN 12311-2:2013 |

| Transversal | ≥500 | ||

| Resistance to tearing/N | Longitudinal | ≥250 | EN 12310-2:2018 |

| Transversal | ≥250 | ||

| Shear Resistance of Joints(N/50mm) | ≥300 | EN 12317-2:2010 | |

| Resistance to static loading | 20kgs, no leakage | EN12730:2015 | |

| Resistance to impact/mm | 1500 | EN12691:2018 | |

| Water-tightness | There is no pressure drop druing the test | EN 1928: 2000 | |

| Durability against aging | There is no pressure drop druing the test | EN 1926:2000 | |

| EN 1847:2009 | |||

| Durability against chemicals | There is no pressure drop druing the test | EN 1928: 2000 | |

| EN 1847:2009 | |||

| Reaction to Fire | Class E | EN13501-1+A1:2009 | |

| Remarks: All the test items acording to EN Standard | |||

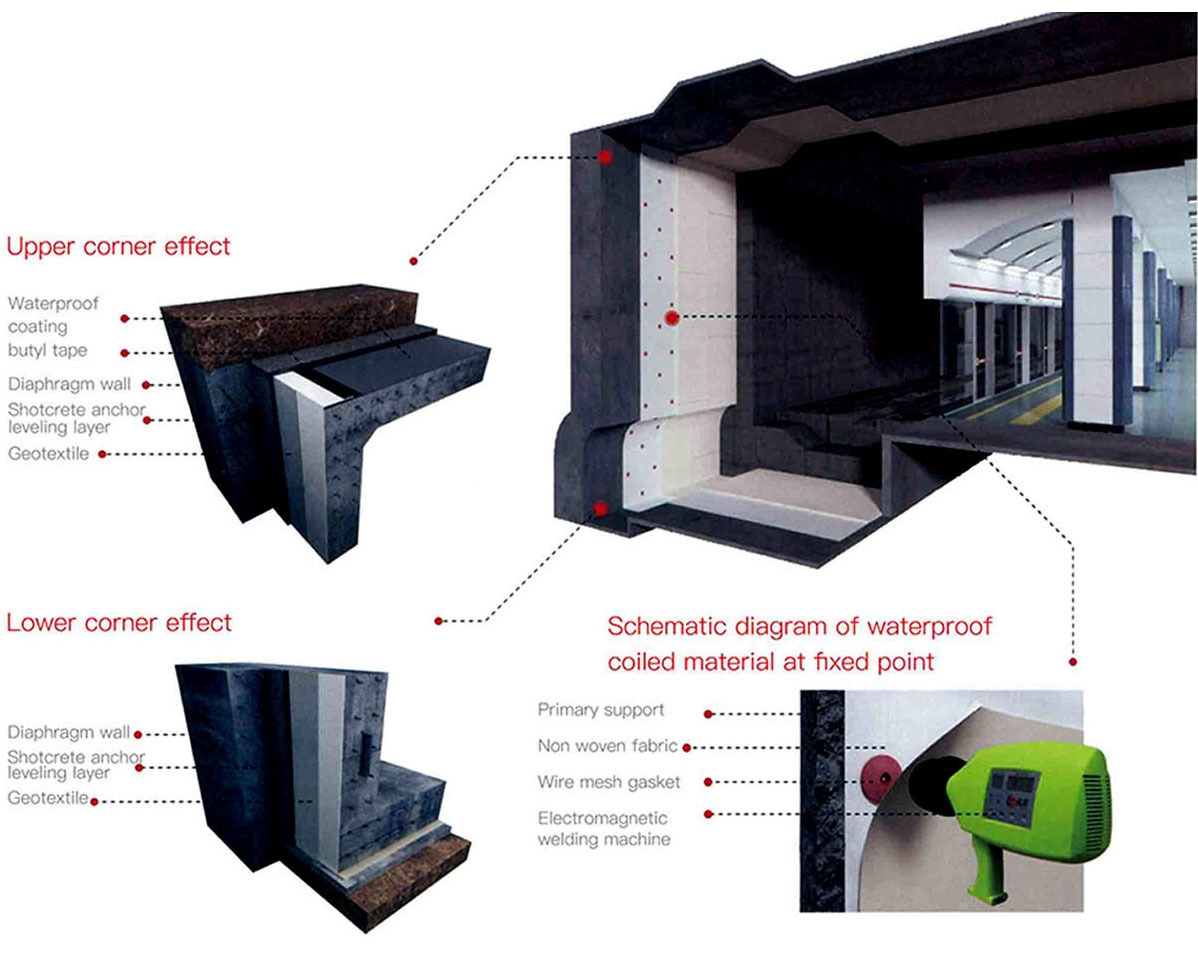

Construction structure node

Advantages

Waterproof and reliable

Permanent seamless bonding with post cast concrete to form a composite waterproof system and eliminate Water channeling.

Excellent mechanical properties and corrosion resistance

The bottom membrane has strong resistance to external force damage and structural deformation, and is resistant to acid, alkali and salt, seawater immersion Resistance to chloride penetration.

Convenient construction, short construction period and strong system compatibility

It can be laid empty with the base course without open water. There is no need to chamfer the additional layer. A variety of overlapping groups are flexible Close; It has good lap compatibility with heterogeneous water proof materials on the roof.

Green environmental protection and safety

Raw materials do not contain harmful substances, and there is no need for open fire and volatile solvent primer in construction.

Reduce the project cost with good economy

The laying of a single course shall meet the requirements of class I waterproof fortification, without protective layer, and the reinforcement shall be bound directly Pouring concrete, low maintenance cost.

Messages